View Poll Results: What are your 5.4L swap plans?

Voters: 220. You may not vote on this poll

Anyone intrested in 5.4L swaps, in here. Need you to opine.

#9303

Yep... TFS heads (porting makes it even better), a MHS stage 3.5 TFS cam and 11:1 compression, longtubes. You should be within spitting distance of 400.

The new intake MHS is working on will help at the top end especially with TFS heads. That's a while away still.

News on the designing things front.

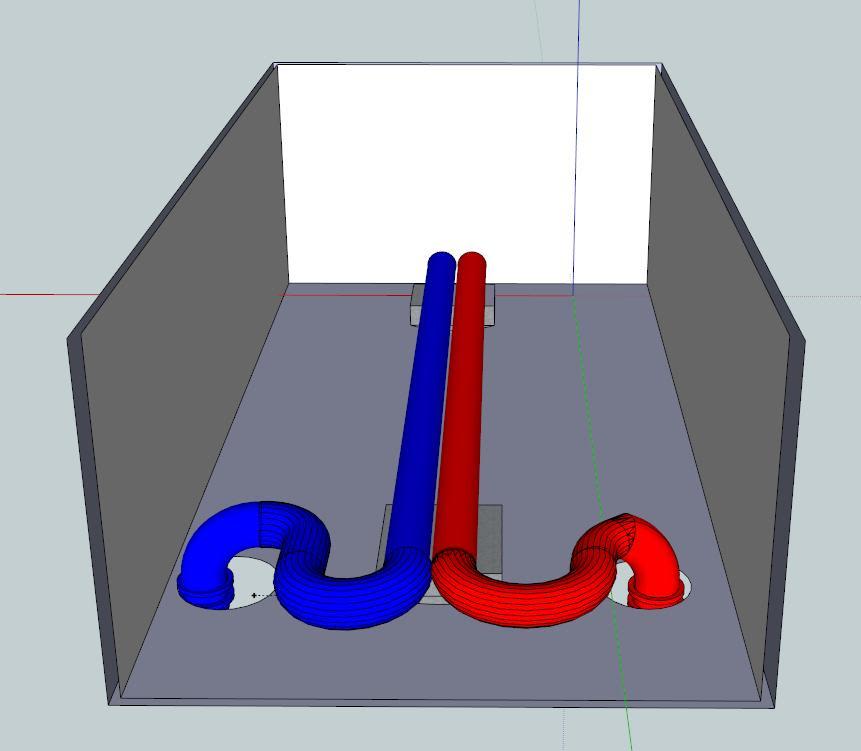

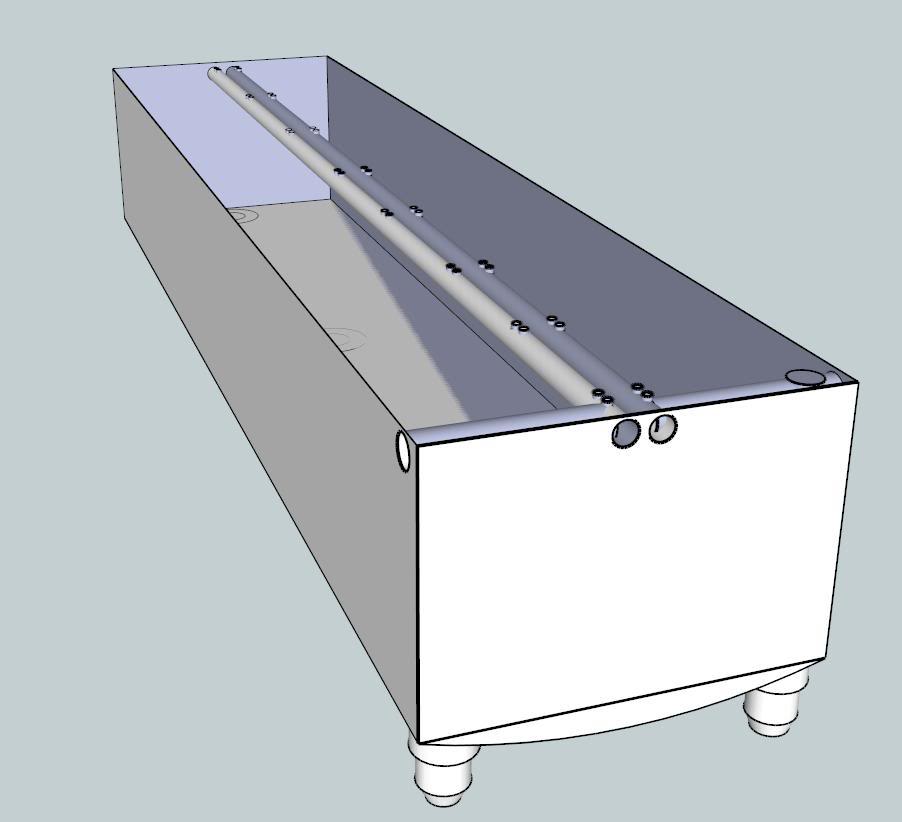

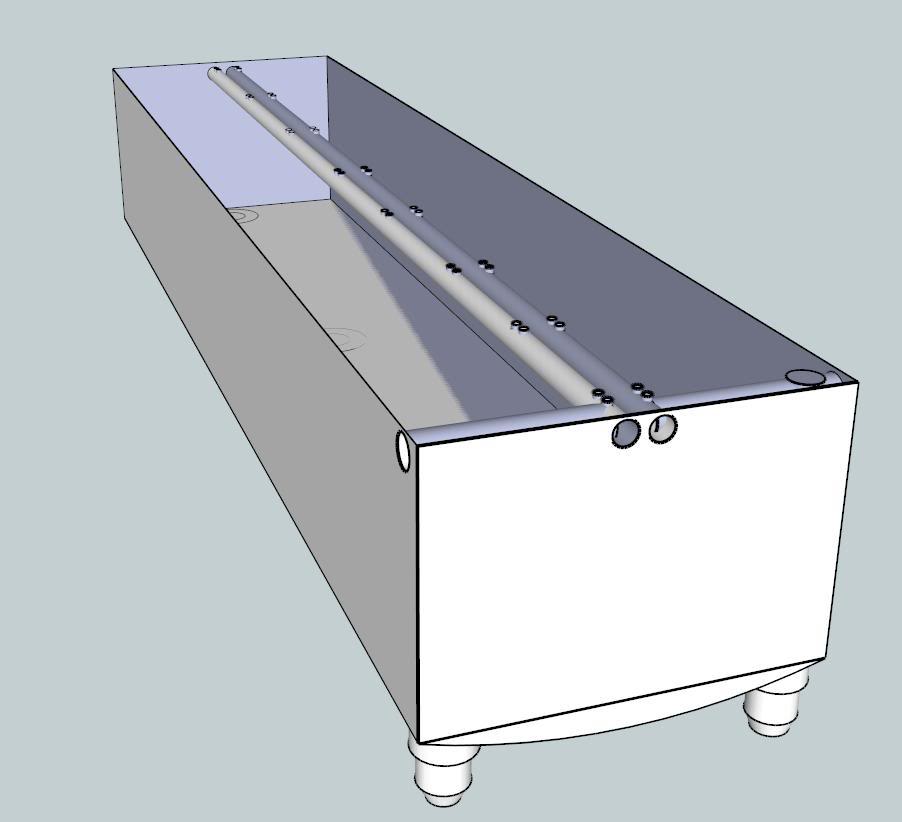

I've been working on finding a supplier that can make the spray bars I need and I finally found one (they're in the UK... no US company would play ball, ********!). The drawings below are not to scale but they'll give you the basic idea of how it'd be laid out if it makes it to production. This is designed specifically for the HPS Hardball'R series of intake manifolds (4.6 and 5.4).

I'm working on another design that's going to be the bastard child of a direct port kit and a plate/bar kit like the one above.

Last edited by r3dn3ck; 06-25-2010 at 08:31 AM.

#9304

What kind of power will i need to be hitting 11s on slicks?

Also can anyone point me to a rotating assembly to put in the 5.4 and such. I was thinking forged just in-case it ever gets old i could turbo it or something. I do know i would have to change cams at that point but thats no biggie to me.

Will getting the engine bored .030 over help any? I want to build a car that is gonna be a all motor beast. Street and track....

Also can anyone point me to a rotating assembly to put in the 5.4 and such. I was thinking forged just in-case it ever gets old i could turbo it or something. I do know i would have to change cams at that point but thats no biggie to me.

Will getting the engine bored .030 over help any? I want to build a car that is gonna be a all motor beast. Street and track....

#9305

look over the last 3 pages... we've been discussing internals. Themustangdepot.com is your best source for rods and pistons for cheap. Summit for bearings and fasteners.

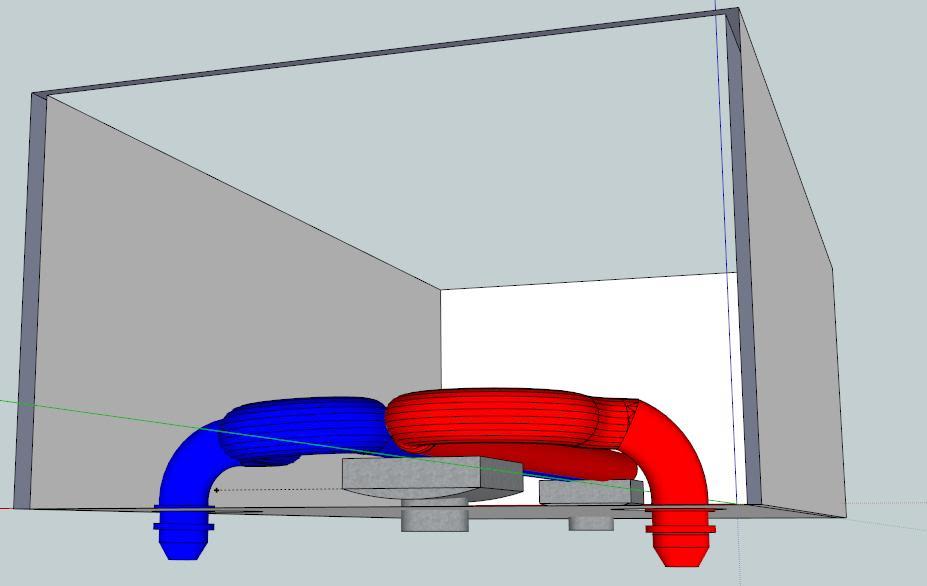

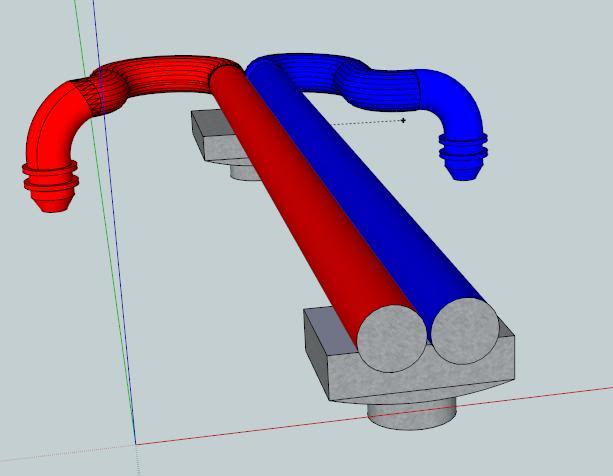

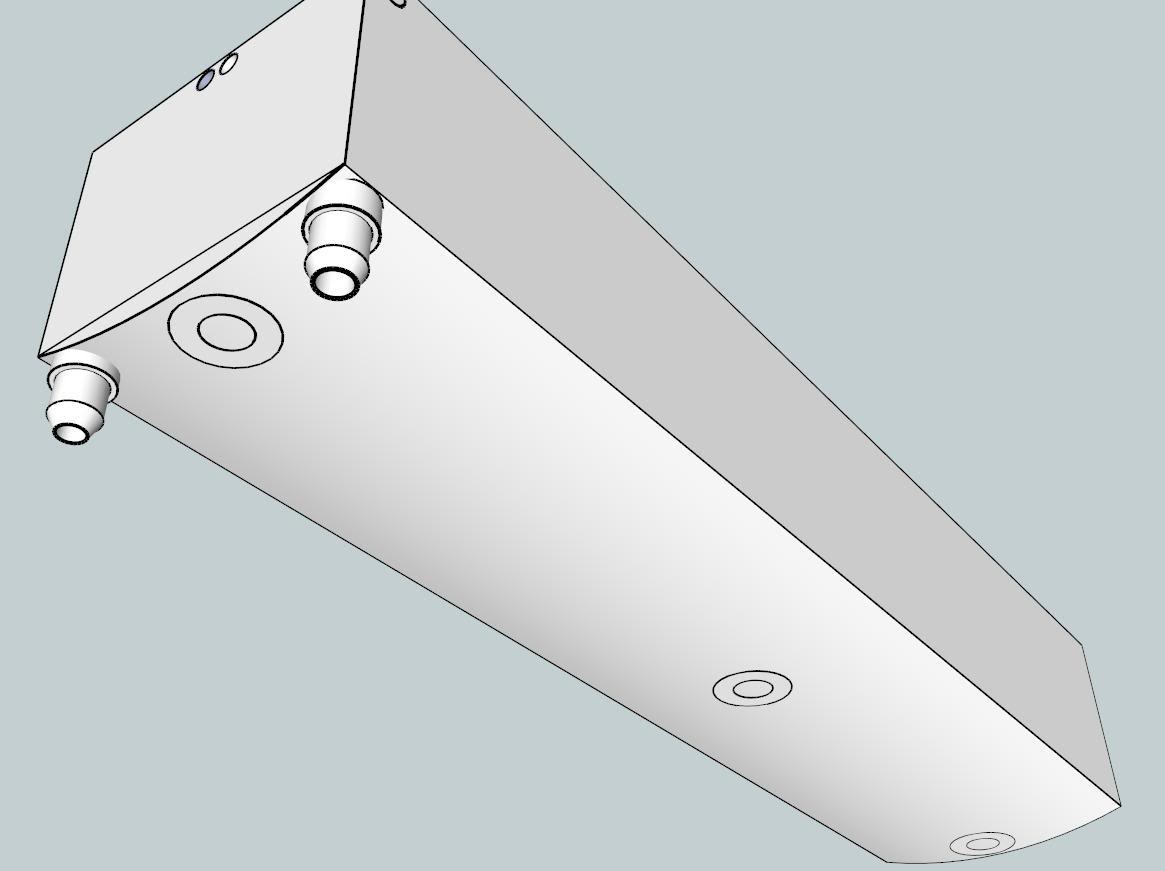

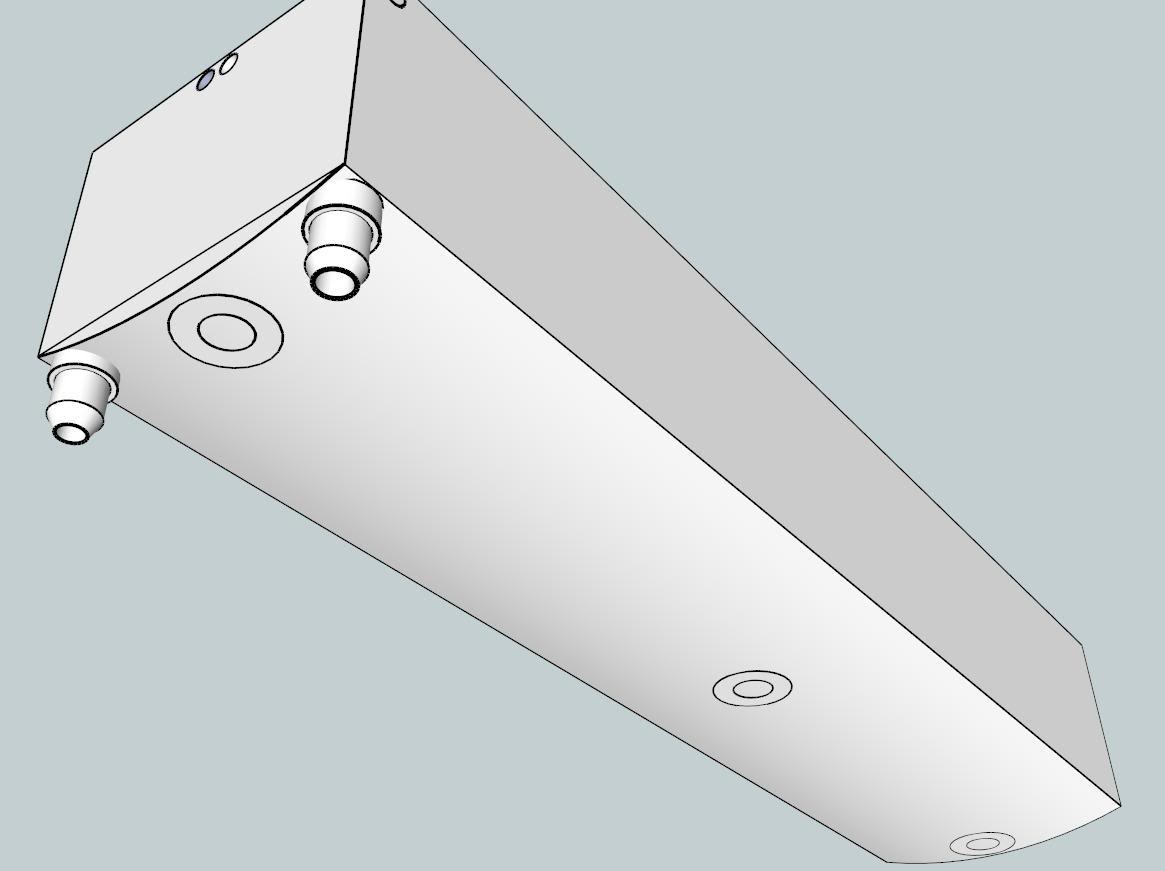

Here's the next version of the nitrous kit, this time as a monoblock with built in nozzles. You can't tell in the pic but the discharge holes are angled toward the intake runners. Also note that I deleted the top panel so you could see the channels on the interior. It looks like a solid block with uninteresting holes in it with the top panel on.

Here's the next version of the nitrous kit, this time as a monoblock with built in nozzles. You can't tell in the pic but the discharge holes are angled toward the intake runners. Also note that I deleted the top panel so you could see the channels on the interior. It looks like a solid block with uninteresting holes in it with the top panel on.

#9306

stopped by FTP today at lunch. Tj said he has 3 sets of LT's getting underway first week of aug. so anyone else wanting them or even turbo headers like mine, go ahead and call to get your name on the list. anyone wanting 400 NA hp will need a set of LT's in the mix...

#9307

I'm getting the ball rolling on my internals, should be able to pick them up sometime in the next couple weeks. Just depends on my paycheck and if I can sell anything. Actually, my paycheck should cover it all but I'll just have to see.

Does anyone have any experience with the PA performance starters? I figured I might as well put in a new starter since I've got the engine out and getting to the starter is a pain and don't want to have to deal with it again later on.

Other than the internals, I'm just going to need a set of cams, a timing cover, some headers, an intake, and a couple other small miscellaneous things here and there and I'll have it all ready to go. It's starting to come together a little quicker than I originally planned but I can still spend a while getting my suspension and body work dialed in like I want it.

Does anyone have any experience with the PA performance starters? I figured I might as well put in a new starter since I've got the engine out and getting to the starter is a pain and don't want to have to deal with it again later on.

Other than the internals, I'm just going to need a set of cams, a timing cover, some headers, an intake, and a couple other small miscellaneous things here and there and I'll have it all ready to go. It's starting to come together a little quicker than I originally planned but I can still spend a while getting my suspension and body work dialed in like I want it.

#9308

Seems like I've been waiting forever for this day, Started planning and buying parts for my build back in Nov 08 and today I finally turned the key on my build. This thread helped me complete my goal and avoid as many headaches as possible. I sure had a fun time moving things around and modding my termi hood to make everything fit, but blah blah blah no one cares they just wanna hear the movie.

Here it is.

http://www.youtube.com/watch?v=RXOCC5GzazU

Heres a better shot of under the hood and mostly done.

Here it is.

http://www.youtube.com/watch?v=RXOCC5GzazU

Heres a better shot of under the hood and mostly done.

#9311

Seems like I've been waiting forever for this day, Started planning and buying parts for my build back in Nov 08 and today I finally turned the key on my build. This thread helped me complete my goal and avoid as many headaches as possible. I sure had a fun time moving things around and modding my termi hood to make everything fit, but blah blah blah no one cares they just wanna hear the movie.

Here it is.

http://www.youtube.com/watch?v=RXOCC5GzazU

Heres a better shot of under the hood and mostly done.

Here it is.

http://www.youtube.com/watch?v=RXOCC5GzazU

Heres a better shot of under the hood and mostly done.

Now that is SWEEEEEEEET indeed ... If that aint motivating I don't know what is.

GREAT JOB - I LOVE IT ~ !!!

#9315

I plan on using a oval throttle body with a 6061.com plenum or the dragon 2v plenum that adapts to the cobra throttle bodies. The throttle cable and the throttle position sensor are on opposite sides on the cobra. It wouldn't be anything but moving the throttle cable to the right side and making a bracket would it and running the TPS to the other side?? I also think some cobra throttle bodies have the IAC on them?

#9319

I wish I had bought a block and built from there. I originally bought a rebuilt 2v longblock and tore it down to a bare block and I'm now rebuilding it with forged internals and 4v heads.

#9320

That's what I'm doing. See above pic. I got a new Ford Racing block, new Ford racing steel crank, 4130 H-beam rods, ARP studs and bolts, Probe forged pistons....

#9321

I plan on using a oval throttle body with a 6061.com plenum or the dragon 2v plenum that adapts to the cobra throttle bodies. The throttle cable and the throttle position sensor are on opposite sides on the cobra. It wouldn't be anything but moving the throttle cable to the right side and making a bracket would it and running the TPS to the other side?? I also think some cobra throttle bodies have the IAC on them?

#9322

I was going to buy a new block before getting a reman shortblock from Ford. For $495 its hard to beat finish machined with new lower end bolts, but if you are planning to put ARP bolts in the bottom you would be paying for bolts twice.

#9323

Yeah, but now I can keep those bolts for future use on something else or sell them to someone doing a stock rebuild. I say it's hard to beat the price for a new block. All the machine work is done, painted, new freeze plugs, all the bores are spot on and standard sized etc. etc. etc. Someone above mentioned that a machine shop rebuilt thier modular and set it up real loose. That is something I was worried about too. That worry is gone if you get a new block. Just my .02, some people may totally disagree and that is ok. Everybody does things thier own way.

#9324

Yep, I'll take the factory machining with no problems. If you are collecting the other parts its a good starting point. If you're like me and don't need forged I couldn't pass up a complete shortblock from Ford for $1023. Should be here today.  Probably gonna be two weeks before I get my heads back though...

Probably gonna be two weeks before I get my heads back though...

Probably gonna be two weeks before I get my heads back though...

Probably gonna be two weeks before I get my heads back though...

#9325

General SpecificationsItemSpecification

Engine — SuperchargedDisplacement5.4L (330 cu in)

Number of cylinders8

Bore90.2 mm (3.55 in)

Stroke105.8 mm (4.17 in)

Firing order1-3-7-2-6-5-4-8

Oil pressure (@ 2000 rpm — hot)275.8-413.7 kPa (40-60 psi)

Oil capacity (includes filter change)5.7 L (6.0 qts)

Compression ratio9.0:1

Cylinder Head and Valve Train

Combustion chamber volume42.45-45.45 cc (2.59-2.77 cu in)

Valve arrangement (front to rear) — LHE-I-E-I-E-I-E-I

Valve arrangement (front to rear) — RHI-E-I-E-I-E-I-E

Valve guide bore diameter7.044-7.015 mm (0.2773-0.2762 in)

Valve stem diameter — intake6.995-6.975 mm (0.2754-0.2746 in)

Valve stem diameter — exhaust6.970-6.949 mm (0.2744-0.2736 in)

Valve stem-to-guide clearance — intake0.069-0.020 mm (0.0027-0.0008 in)

Valve stem-to-guide clearance — exhaust0.095-0.045 mm (0.0037-0.0018 in)

Valve head diameter — intake44.63-44.37 mm (1.7571-1.7469 in)

Valve head diameter — exhaust36.01 mm (1.4177 in)

Valve face runout0.05 mm (0.0020 in)

Valve face angle45.75-45.25 degrees

Valve seat width — intake1.3-1.5 mm (0.0512-0.0591 in)

Valve seat width — exhaust2.1-1.9 mm (0.0827-0.0748 in)

Valve seat runout (T.I.R.)0.025 mm (0.0010 in)

Valve seat angle45.50 degrees

Valve spring free length53.37 mm (2.10 in)

Valve spring squareness2.0 degrees

Valve spring compression pressure720-800 N (161.862-179.847 lb) @ 28.02 mm (1.10 in)

Valve spring installed height42.9-42.3 mm (1.6890-1.6654 in)

Valve spring installed pressure — valve open760 N @ 28.80 mm (170.855 lb @ 1.1339 in)

Valve spring installed pressure — valve closed302 N @ 42.56 mm (67.8923 lb @ 1.6756 in)

Roller follower ratio1.75:1

Hydraulic Lash Adjuster

Diameter16.000-15.988 mm (0.6299-0.6295 in)

Clearance-to-bore0.018-0.069 mm (0.0007-0.0027 in)

Service limit 0.016 mm (0.0006 in)

Hydraulic leakdown rate5-25 seconds

Collapsed lash adjuster gap 0.085-0.450 mm (0.0335-0.0177 in)

Camshaft

Theoretical valve lift @ 0 lash — intake12.02 mm (0.4732 in)

Theoretical valve lift @ 0 lash — exhaust12.67 mm (0.4988 in)

Lobe lift — intake7.1104 mm (0.2799 in)Lobe lift — exhaust7.4979 mm (0.2952 in)

Allowable lobe lift loss0Journal diameter26.962-26.936 mm (1.0615-1.0605 in)

Camshaft journal bore inside diameter (cap assembled)27.012-26.987 mm (1.0635-1.0625 in)

Camshaft journal-to-bearing clearance0.076-0.025 mm (0.0030-0.0010 in)Runoutb 0.03 mm (0.0012 in)

End play0.0270-0.0190 mm (0.0011-0.0075 in)

Cylinder Block

Cylinder bore diameter — grade 190.200-90.210 mm (3.5512-3.5516 in)

Cylinder bore diameter — grade 290.210-90.220 mm (3.5516-3.5520 in)

Cylinder bore diameter — grade 390.220-90.230 mm (3.5520-3.5524 in)

Cylinder bore maximum taper0.006 mm (0.0002 in)

Cylinder bore maximum out-of-round0.020 mm (0.0008 in)

Main bearing bore inside diameter72.401-72.422 mm (2.850-2.851 in)

Crankshaft

Main bearing journal diameter 67.483-67.503 mm (2.6568-2.6576 in)

Main bearing journal maximum taper (straightness)0.004 mm (0.0002 in)

Main bearing journal maximum out-of-round0.0075 mm (0.0003 in) between cross sections

Main bearing journal-to-cylinder block clearance0.048-0.024 mm (0.0019-0.0009 in)

Connecting rod journal diameter53.003-52.983 mm (2.0867-2.0859 in)

Connecting rod journal maximum taper0.004 mm (0.0002 in)

Connecting rod journal maximum out-of-round0.0075 mm (0.0003 in) between cross sections

Crankshaft maximum end play0.075-0.377 mm (0.0030-0.0148 in)

Piston and Connecting Rod

Piston diameter — grade 1 (at right angle to pin bore)90.175-90.165 mm (3.5502-3.5498 in)

Piston diameter — grade 2 (at right angle to pin bore)90.185-90.175 mm (3.5506-3.5502 in)

Piston diameter — grade 3 (at right angle to pin bore)90.195-90.185 mm (3.5510-3.5506 in)

Piston-to-cylinder bore clearance (at grade size)0.025-0.045 mm (0.0010-0.0018 in)

Piston ring end gap — top0.13-0.28 mm (0.0051-0.0110 in)

Piston ring end gap — intermediate0.25-0.40 mm (0.0098-0.0158 in)

Piston ring end gap — oil control0.15-0.65 mm (0.0059-0.0256 in)

Piston ring groove width — top1.53-1.55 mm (0.0602-0.0610 in)

Piston ring groove width — intermediate1.52-1.54 mm (0.0598-0.0606 in)

Piston ring groove width — oil control3.030-3.050 mm (0.1193-0.1201 in)

Piston ring width1.49-1.46 mm (0.0587-0.0575 in)

Piston ring-to-groove clearance — top0.030-0.050 mm (0.0012-0.0020 in)

Piston ring-to-groove clearance — intermediate0.030-0.080 mm (0.0012-0.0031 in)

Piston pin bore diameter22.008-22.014 mm (0.8665-0.8667 in)

Piston pin diameter22.0005-22.0030 mm (0.8662-0.8663 in)

Piston pin length61.8 mm (2.433 in)

Piston pin-to-piston fit (clearance)0.005-0.0135 mm (0.0002-0.0005 in)

Connecting rod-to-pin clearance0.0185-0.0325 mm (0.0007-0.0013 in)

Connecting rod pin bore diameter22.012-22.024 mm (0.8666-0.8671 in)

Connecting rod length (centerline bore-to-bore)169.1 mm (6.6575 in)

Connecting rod maximum allowed bendą 0.038 mm (0.0015 in)

Connecting rod maximum allowed twistą 0.05 mm (0.0020 in)

Connecting rod bearing bore diameter (with assembled liners)53.049-53.027 mm (2.0885-2.0877 in)

Connecting rod bearing-to-crankshaft clearance0.064-0.026 mm (0.0025-0.0010 in)

Connecting rod side clearance0.475-0.125 mm (0.0187-0.0049 in)

a Time required for the plunger to leak down 1.6 mm of travel with 222 N force and leak-down fluid in the lash adjuster.

b Full indicator measurement on all journals when supported on front and rear journals (4 places).

Torque Specifications

DescriptionNmlb-ftlb-inValve cover bolts10—89Camshaft bearing cap bolts10—89Camshaft sprocket boltsa ———Cylinder head temperature sensor (CHT)2619—Camshaft position sensor bolt10—89Crankshaft position sensor bolt10—89Connecting rod boltsa———Crankshaft damper pulley bolta———Crankshaft main bearing bolts (cross-mounted)a———Crankshaft main bearing bolts (vertical)a———Cylinder heads boltsa———EGR valve to intake manifold boltsa———Exhaust manifold nuts2518—Exhaust manifold studs129—Exhaust manifold-to-Y-pipe nuts4030—Drive belt idler pulley bolt2518—Flywheel bolts8059—Engine front cover boltsa———Transmission-to-engine bolts4835—Torque converter-to-flexplate nuts3526—Fuel injection supply manifold bracket bolts10—89Generator upper mounting bracket bolts10—89Generator lower mounting bolts2518—Heater return tube studs4030—Ignition coil6—53Lower intake manifold to upper intake manifold boltsa———Upper intake manifold to cylinder head boltsa———Intake manifold tuning valve screwsa———Knock sensor2015—Oil filter1612—Oil filter adapter bolts2518—Oil level indicator tube bolt10—89Oil line connector adapter assembly bolt2518—Oil pan boltsa———Oil pan drain plug1410—Oil pressure switch1410—Oil pump bolts10—89Oil pump screen and pickup tube bolts10—89Oil pump screen and pickup tube spacer2518—Oil pump screen and pickup tube spacer bolt2518—Power steering pump bolts2518—Rear main oil seal retainer bolts10—89Spark plugs1813—Thermostat housing bolts10—89Idle air control valve screwsa———Throttle body spacer-to-intake manifold bolts10—89Throttle body-to-throttle body spacer boltsa———Timing chain guide bolts10—89Timing chain hydraulic tensioner bolts2518—Water pump bolts2518—Water pump pulley bolts2518—Exhaust manifold to EGR valve tube fittingsa———Brake booster vacuum hose bracket nut10—89Power steering reservoir upper bracket-to-thermostat housing bolt118—Power steering reservoir upper bracket-to-middle bracket bolts1713—Power steering reservoir middle bracket-to-lower bracket bolts2317—Power steering reservoir lower bracket-to-engine cylinder head bolts8059—38-pin bulkhead connector bolt5—4442-pin bulkhead connector bolt5—44Bulkhead connector bracket cover bolts129—Bulkhead connector bracket-to-cowl bolts129—Starter relay nuts8—71Accelerator control splash shield bolts7—62Accelerator cable bracket bolts10—89Motor mount to cylinder block bolts6344—Motor mount through bolts9066—Oil pressure switch1410—Fan shroud bolts9—80Differential pressure feedback EGR sensor nuts (5.4L)10—89Differential pressure feedback EGR sensor bracket nut (5.4L)10—89Differential pressure feedback EGR sensor bracket bolt (5.4L)10—89Supercharged Engines OnlyPower steering bracket lower bolts4030—Power steering bracket upper bolt10—89Ground strap nut10—89Fuel injection supply manifold bolts10—89Ignition coil bolts5—44Generator bracket bolts10—89Intake manifold boltsa———Crankshaft damper pulley bolta———Auxiliary crankshaft pulley10074—Auxiliary crankshaft pulley brace nuts4835—Transmission cooler line bracket nut1511—Power steering shield nut1511—Supercharger pulley adapter bolts4835—a Refer to the procedure in this section.

Engine — SuperchargedDisplacement5.4L (330 cu in)

Number of cylinders8

Bore90.2 mm (3.55 in)

Stroke105.8 mm (4.17 in)

Firing order1-3-7-2-6-5-4-8

Oil pressure (@ 2000 rpm — hot)275.8-413.7 kPa (40-60 psi)

Oil capacity (includes filter change)5.7 L (6.0 qts)

Compression ratio9.0:1

Cylinder Head and Valve Train

Combustion chamber volume42.45-45.45 cc (2.59-2.77 cu in)

Valve arrangement (front to rear) — LHE-I-E-I-E-I-E-I

Valve arrangement (front to rear) — RHI-E-I-E-I-E-I-E

Valve guide bore diameter7.044-7.015 mm (0.2773-0.2762 in)

Valve stem diameter — intake6.995-6.975 mm (0.2754-0.2746 in)

Valve stem diameter — exhaust6.970-6.949 mm (0.2744-0.2736 in)

Valve stem-to-guide clearance — intake0.069-0.020 mm (0.0027-0.0008 in)

Valve stem-to-guide clearance — exhaust0.095-0.045 mm (0.0037-0.0018 in)

Valve head diameter — intake44.63-44.37 mm (1.7571-1.7469 in)

Valve head diameter — exhaust36.01 mm (1.4177 in)

Valve face runout0.05 mm (0.0020 in)

Valve face angle45.75-45.25 degrees

Valve seat width — intake1.3-1.5 mm (0.0512-0.0591 in)

Valve seat width — exhaust2.1-1.9 mm (0.0827-0.0748 in)

Valve seat runout (T.I.R.)0.025 mm (0.0010 in)

Valve seat angle45.50 degrees

Valve spring free length53.37 mm (2.10 in)

Valve spring squareness2.0 degrees

Valve spring compression pressure720-800 N (161.862-179.847 lb) @ 28.02 mm (1.10 in)

Valve spring installed height42.9-42.3 mm (1.6890-1.6654 in)

Valve spring installed pressure — valve open760 N @ 28.80 mm (170.855 lb @ 1.1339 in)

Valve spring installed pressure — valve closed302 N @ 42.56 mm (67.8923 lb @ 1.6756 in)

Roller follower ratio1.75:1

Hydraulic Lash Adjuster

Diameter16.000-15.988 mm (0.6299-0.6295 in)

Clearance-to-bore0.018-0.069 mm (0.0007-0.0027 in)

Service limit 0.016 mm (0.0006 in)

Hydraulic leakdown rate5-25 seconds

Collapsed lash adjuster gap 0.085-0.450 mm (0.0335-0.0177 in)

Camshaft

Theoretical valve lift @ 0 lash — intake12.02 mm (0.4732 in)

Theoretical valve lift @ 0 lash — exhaust12.67 mm (0.4988 in)

Lobe lift — intake7.1104 mm (0.2799 in)Lobe lift — exhaust7.4979 mm (0.2952 in)

Allowable lobe lift loss0Journal diameter26.962-26.936 mm (1.0615-1.0605 in)

Camshaft journal bore inside diameter (cap assembled)27.012-26.987 mm (1.0635-1.0625 in)

Camshaft journal-to-bearing clearance0.076-0.025 mm (0.0030-0.0010 in)Runoutb 0.03 mm (0.0012 in)

End play0.0270-0.0190 mm (0.0011-0.0075 in)

Cylinder Block

Cylinder bore diameter — grade 190.200-90.210 mm (3.5512-3.5516 in)

Cylinder bore diameter — grade 290.210-90.220 mm (3.5516-3.5520 in)

Cylinder bore diameter — grade 390.220-90.230 mm (3.5520-3.5524 in)

Cylinder bore maximum taper0.006 mm (0.0002 in)

Cylinder bore maximum out-of-round0.020 mm (0.0008 in)

Main bearing bore inside diameter72.401-72.422 mm (2.850-2.851 in)

Crankshaft

Main bearing journal diameter 67.483-67.503 mm (2.6568-2.6576 in)

Main bearing journal maximum taper (straightness)0.004 mm (0.0002 in)

Main bearing journal maximum out-of-round0.0075 mm (0.0003 in) between cross sections

Main bearing journal-to-cylinder block clearance0.048-0.024 mm (0.0019-0.0009 in)

Connecting rod journal diameter53.003-52.983 mm (2.0867-2.0859 in)

Connecting rod journal maximum taper0.004 mm (0.0002 in)

Connecting rod journal maximum out-of-round0.0075 mm (0.0003 in) between cross sections

Crankshaft maximum end play0.075-0.377 mm (0.0030-0.0148 in)

Piston and Connecting Rod

Piston diameter — grade 1 (at right angle to pin bore)90.175-90.165 mm (3.5502-3.5498 in)

Piston diameter — grade 2 (at right angle to pin bore)90.185-90.175 mm (3.5506-3.5502 in)

Piston diameter — grade 3 (at right angle to pin bore)90.195-90.185 mm (3.5510-3.5506 in)

Piston-to-cylinder bore clearance (at grade size)0.025-0.045 mm (0.0010-0.0018 in)

Piston ring end gap — top0.13-0.28 mm (0.0051-0.0110 in)

Piston ring end gap — intermediate0.25-0.40 mm (0.0098-0.0158 in)

Piston ring end gap — oil control0.15-0.65 mm (0.0059-0.0256 in)

Piston ring groove width — top1.53-1.55 mm (0.0602-0.0610 in)

Piston ring groove width — intermediate1.52-1.54 mm (0.0598-0.0606 in)

Piston ring groove width — oil control3.030-3.050 mm (0.1193-0.1201 in)

Piston ring width1.49-1.46 mm (0.0587-0.0575 in)

Piston ring-to-groove clearance — top0.030-0.050 mm (0.0012-0.0020 in)

Piston ring-to-groove clearance — intermediate0.030-0.080 mm (0.0012-0.0031 in)

Piston pin bore diameter22.008-22.014 mm (0.8665-0.8667 in)

Piston pin diameter22.0005-22.0030 mm (0.8662-0.8663 in)

Piston pin length61.8 mm (2.433 in)

Piston pin-to-piston fit (clearance)0.005-0.0135 mm (0.0002-0.0005 in)

Connecting rod-to-pin clearance0.0185-0.0325 mm (0.0007-0.0013 in)

Connecting rod pin bore diameter22.012-22.024 mm (0.8666-0.8671 in)

Connecting rod length (centerline bore-to-bore)169.1 mm (6.6575 in)

Connecting rod maximum allowed bendą 0.038 mm (0.0015 in)

Connecting rod maximum allowed twistą 0.05 mm (0.0020 in)

Connecting rod bearing bore diameter (with assembled liners)53.049-53.027 mm (2.0885-2.0877 in)

Connecting rod bearing-to-crankshaft clearance0.064-0.026 mm (0.0025-0.0010 in)

Connecting rod side clearance0.475-0.125 mm (0.0187-0.0049 in)

a Time required for the plunger to leak down 1.6 mm of travel with 222 N force and leak-down fluid in the lash adjuster.

b Full indicator measurement on all journals when supported on front and rear journals (4 places).

Torque Specifications

DescriptionNmlb-ftlb-inValve cover bolts10—89Camshaft bearing cap bolts10—89Camshaft sprocket boltsa ———Cylinder head temperature sensor (CHT)2619—Camshaft position sensor bolt10—89Crankshaft position sensor bolt10—89Connecting rod boltsa———Crankshaft damper pulley bolta———Crankshaft main bearing bolts (cross-mounted)a———Crankshaft main bearing bolts (vertical)a———Cylinder heads boltsa———EGR valve to intake manifold boltsa———Exhaust manifold nuts2518—Exhaust manifold studs129—Exhaust manifold-to-Y-pipe nuts4030—Drive belt idler pulley bolt2518—Flywheel bolts8059—Engine front cover boltsa———Transmission-to-engine bolts4835—Torque converter-to-flexplate nuts3526—Fuel injection supply manifold bracket bolts10—89Generator upper mounting bracket bolts10—89Generator lower mounting bolts2518—Heater return tube studs4030—Ignition coil6—53Lower intake manifold to upper intake manifold boltsa———Upper intake manifold to cylinder head boltsa———Intake manifold tuning valve screwsa———Knock sensor2015—Oil filter1612—Oil filter adapter bolts2518—Oil level indicator tube bolt10—89Oil line connector adapter assembly bolt2518—Oil pan boltsa———Oil pan drain plug1410—Oil pressure switch1410—Oil pump bolts10—89Oil pump screen and pickup tube bolts10—89Oil pump screen and pickup tube spacer2518—Oil pump screen and pickup tube spacer bolt2518—Power steering pump bolts2518—Rear main oil seal retainer bolts10—89Spark plugs1813—Thermostat housing bolts10—89Idle air control valve screwsa———Throttle body spacer-to-intake manifold bolts10—89Throttle body-to-throttle body spacer boltsa———Timing chain guide bolts10—89Timing chain hydraulic tensioner bolts2518—Water pump bolts2518—Water pump pulley bolts2518—Exhaust manifold to EGR valve tube fittingsa———Brake booster vacuum hose bracket nut10—89Power steering reservoir upper bracket-to-thermostat housing bolt118—Power steering reservoir upper bracket-to-middle bracket bolts1713—Power steering reservoir middle bracket-to-lower bracket bolts2317—Power steering reservoir lower bracket-to-engine cylinder head bolts8059—38-pin bulkhead connector bolt5—4442-pin bulkhead connector bolt5—44Bulkhead connector bracket cover bolts129—Bulkhead connector bracket-to-cowl bolts129—Starter relay nuts8—71Accelerator control splash shield bolts7—62Accelerator cable bracket bolts10—89Motor mount to cylinder block bolts6344—Motor mount through bolts9066—Oil pressure switch1410—Fan shroud bolts9—80Differential pressure feedback EGR sensor nuts (5.4L)10—89Differential pressure feedback EGR sensor bracket nut (5.4L)10—89Differential pressure feedback EGR sensor bracket bolt (5.4L)10—89Supercharged Engines OnlyPower steering bracket lower bolts4030—Power steering bracket upper bolt10—89Ground strap nut10—89Fuel injection supply manifold bolts10—89Ignition coil bolts5—44Generator bracket bolts10—89Intake manifold boltsa———Crankshaft damper pulley bolta———Auxiliary crankshaft pulley10074—Auxiliary crankshaft pulley brace nuts4835—Transmission cooler line bracket nut1511—Power steering shield nut1511—Supercharger pulley adapter bolts4835—a Refer to the procedure in this section.

Last edited by r3dn3ck; 06-29-2010 at 02:33 PM. Reason: easier to read now. Tq specs still looks like ass though.

#9329